Radiant Fabrication

My startup experience. It didn’t make me independently wealthy, but I learned an incredible amount about starting and running a company, managing people, and developing a commercial product.

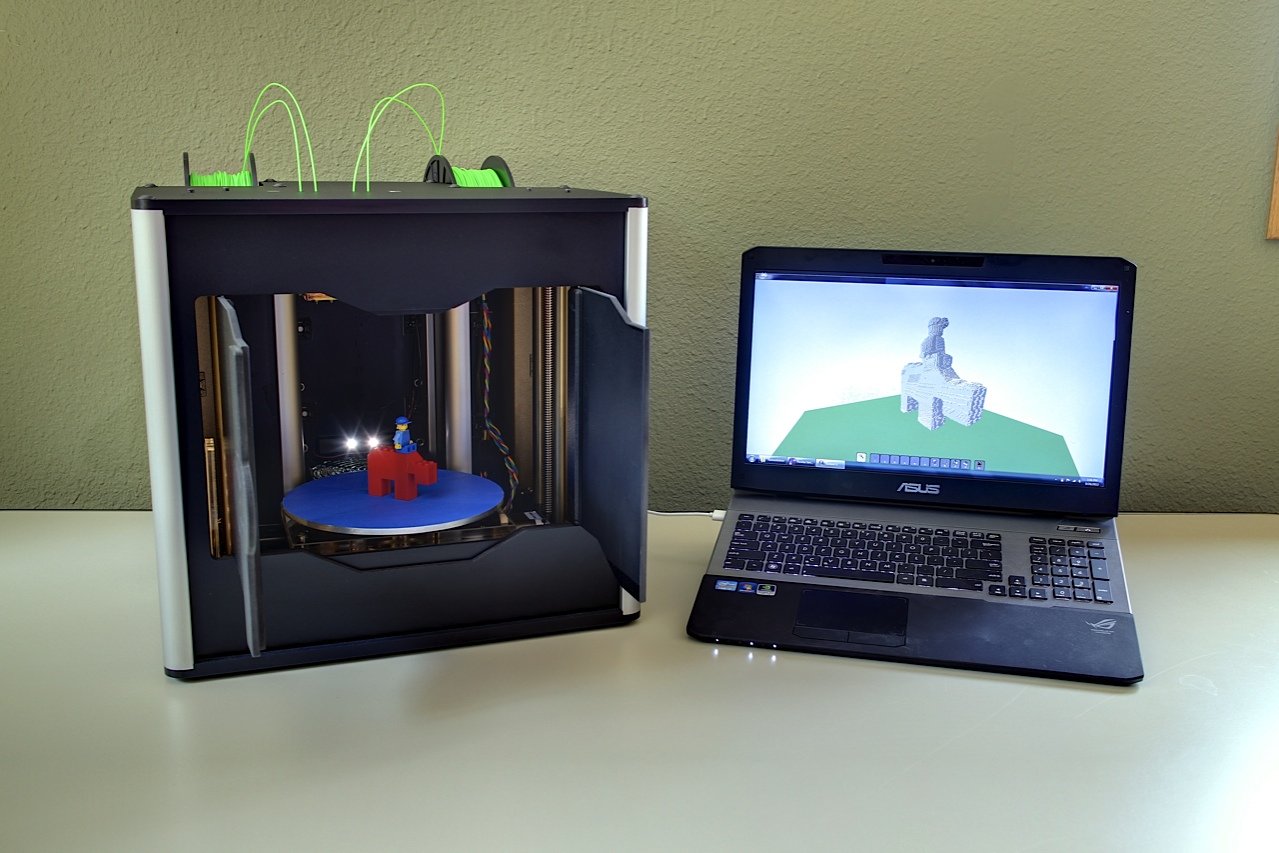

I started Radiant Fabrication in 2011 (closed in 2015) with a couple of co-workers from the Morgridge Institute for Research with the goal of commercializing a 3D printing platform we co-invented. We created a software and hardware combination designed for the K-12 educational market. It was a 4-color 3D printer which included a 3D scanner and came with our own 3D modeling and printing software. Children as young as 5 were able to sit down and start making objects within a few minutes.

On the technical side, I developed most of the printing path generation and 3D scanning functionality. I prototyped all of our initial electronics for our 8 motor CNC machine, which could be expanded to 12 motors for 8 printheads total by stacking PCBs. I also performed countless experiments and component testing.

On the business side, I handled most investor relations and was responsible for securing investments (Angel round was ~$500,000). I also handled all tradeshows exhibits, in-school demonstrations, and in-person customer technical support so that I could get first-hand knowledge on what was and was not working as intended.

I was in charge of hiring, accounting, outreach, and even janitorial duties. I learned I can do all of the things required for a startup, but it took a while for me to realize there aren’t enough hours in the day for me to do everything.

Software used: Solidworks, Unity

Languages used: C++, C#

Related Patents:

Three-Dimensional Printing System Using Dual Rotation Axes

Fixed Printhead Fused Filament Fabrication Printer And Method

A younger me…